Labor Safety and Health

The Environment, Safety and Health (ESH)

ESH Policies and Targets

| Policies | Initiatives (Targets) | |

|---|---|---|

| Environment (E) |

|

|

| Safety (S) |

|

|

| Health (H) |

|

|

- *Rate of lost-worktime injuries: The frequency of work-related accidents, expressed as the number of people experiencing lost-worktime injuries per 1 million working hours

Policies, Targets and Results Related to the Environment (E)

Preserving the global environment is an important international topic from the perspective of sustainable development, as well as an important priority for companies. The Teijin Frontier Group strives to preserve the global environment in accordance with the Teijin Group Global Environmental Charter and the Teijin Group Global Environmental Activity Goals.

At our own factories and those of Group companies, we carry out quality control as a manufacturer, as well as establishing and operating environment, disaster prevention and safety, and health (ESH) management systems. We also ask that partner factories operate management systems to a similar level. As a result of our efforts, our environmental conservation and accident-prevention measures are regarded highly by public institutions in various regions.

In particular, Group companies Nantong Teijin and Teijin Automotive Fabrics Finishing (Jiangsu Province, China) are highly regarded for their contribution to China's corporate environment. Accordingly, the companies have been certified as "green companies" (the highest ranking) by the Environmental Protection Department of Jiangsu.

Working to Conserve the Environment in Local Communities

At our factories, we strive to reduce emissions of chemical and other substances to keep from polluting the environment in local communities.

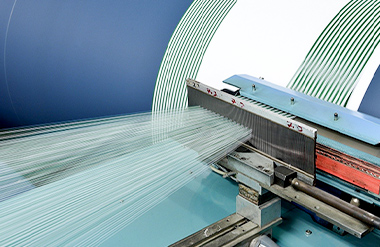

For example, in China Nantong Teijin employs advanced processes such as using reverse osmosis membranes to process wastewater.

- The photo on the right shows wastewater before treatment, while the left-hand photo shows treated wastewater.

Policies, Targets and Results Related to Safety (S)

To eliminate occupational accidents, Teijin Frontier shares its experiences in the "5S" initiative (five Japanese words [seiri, seiton, seisou, seiketsu and shitsuke], which correspond to organization, tidiness, cleaning, hygiene and discipline), and the "Hiyari-Hatto" (meaning close call or near miss) initiative. In addition, we conduct safety patrols and other prevention efforts to stamp out all unsafe work practices and conditions.

Since 2013, the entire Teijin Frontier Group has stepped up efforts to prevent injuries from rotating equipment. To prevent accidents that involve people becoming entangled in equipment, we conduct safety patrols at manufacturing sites and keep all parties informed about prohibited work activities.

Policies and Awareness Activities Related to Health (H)

To provide employees with a healthy working environment, we are working to reduce extensive overtime hours and undertaking improvements to enhance mental health and addressing lifestyle diseases.

The Teijin Group has introduced a "heart hotline" for employees that utilizes institutions from the external Employee Assistance Program (EAP) to perform consultation and counseling by telephone and email. Each year, the Teijin Group conducts diagnosis to measure the "iki-iki" (cheerfulness) level of individuals and workplaces as a statutory stress check. Similarly, the Teijin Frontier Group encourages all employees to be aware of their own stress levels. We also promote improvement activities aimed at creating an amenable working environment.

Occupational health and safety management system

| 社名 | 拠点名 | 認証 |

|---|---|---|

| NANTONG TEIJIN CO., LTD. | Nantong (China) | Work Safety Standarization Second-Level |

| N.I. TEIJIN AIRBAG FABRIC (NANTONG) CO. LTD. |

Nantong (China) | Work Safety Standarization Third-Level |

| NANTONG TEIJIN AUTOMOTIVE FABRICS FINISHING CO., LTD. | Nantong (China) | Work Safety Standarization Third-Level |

| TEIJIN PRODUCT DEVELOPMENT CHINA CO., LTD. | Nantong (China) | Work Safety Standarization Third-Level |

| THAI NAMSIRI INTERTEX CO., LTD. | Wellgrow factory, Bangpoo factory (Thailand) | OHSAS18001 |

| Teijin Polyester (Thailand) Limited | Pathum Thani (Thailand ) | ISO45001 |

| Teijin (Thailand) Limited | Ayutthaya (Thailand ) | ISO45001 |